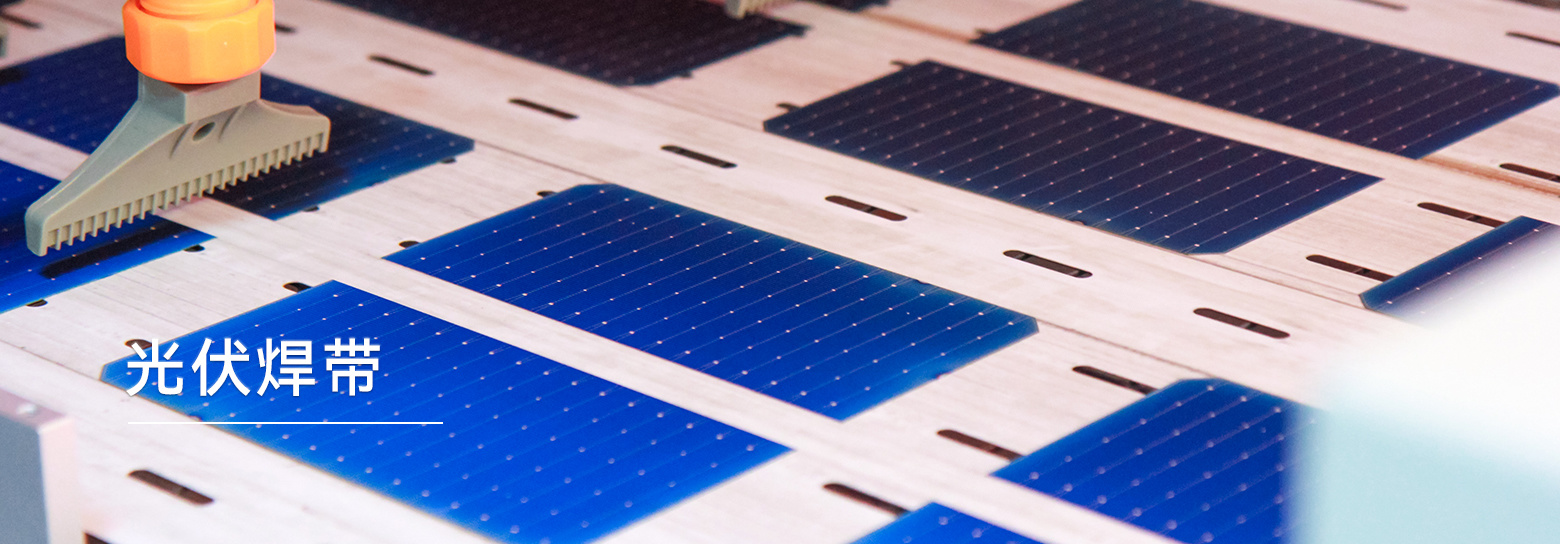

Photovoltaic Ribbon

Photovoltaic Ribbon

Project Introduction

Photovoltaic ribbon, also known as tin-coated ribbon, is used for the series or parallel connection of photovoltaic cells, playing a vital role in conducting and collecting electricity.

SunTech: A Pioneer in the Ribbon Industry, Lead Drafting Organization of the National Standard.

Interconnection Ribbon

SMBB: Wire diameter ≤ 0.26mm. While delivering the performance of conventional MBB ribbon, it can be applied to 16BB or even more busbar modules. The reduced wire diameter decreases the consumption of both ribbon and EVA within the module.

HIT Low-Temperature: Uses solder alloy with a melting point below 180°C as the raw material, enabling low-temperature soldering, which helps reduce cell breakage rates.

Segmented Shaped: Produced using a segmented rolling process, this ribbon consists of round sections and flat sections. The round sections are soldered to the front of the cell, and the flat sections to the back, primarily used in advanced half-cell modules.

| Ribbon | ||

| Specification | ||

| Wire diameter | ||

| Size | Tolerance | |

| Core (Before Plating) | 0.20-0.32 | -0.005~+0.005 |

| Product (After plating) | 0.22-0.35 | -0.005~+0.015 |

| Copper No. | 2-2 TU1 Oxygen-Free Copper | |

| Coating No. | 3-2 ZHLSn60PbA | |

| Camber |

≤5‰ (for automation use) |

|

Busbar

IBC Busbar: SunTech can customize stamping according to customer's die specifications. Capable of mass production with thickness below 0.1mm and width above 15mm.

Black Busbar: The main components of the black coating are amino resin, acrylic resin, and epoxy resin mixed in proportion to form a composite resin, featuring high-temperature resistance and strong coating adhesion.

Embossed Busbar: Features precise and stable single-side reflective embossing patterns for domestic and international applications. Customizable tin coating thickness tolerance, capable of increasing module power output by over 2W.

| Busbar | Busbar | |||||||

| Specification | Specification | |||||||

| Thickness of Core | Width of Core | Thickness of Core | Width of Core | |||||

| Size | Tolerance | Size | Tolerance | Size | Tolerance | |||

| Core (Before Plating) | 0.20 | -0.01~+0.01 | 7.00 | ±0.05 | 0.25 | -0.01~+0.01 | 7.00 | ±0.05 |

| Product (After plating) | 0.25 | -0.015~+0.015 | 7.00 | ±0.1 | 0.30 | -0.015~+0.015 | 7.00 | ±0.1 |

| Copper No. | 2-2 TU1 Oxygen-Free Copper | 2-2 TU1 Oxygen-Free Copper | ||||||

| Coating No. | 3-2 ZHLSn60PbA | 3-2 ZHLSn60PbA | ||||||

| Camber |

≤3‰ (cut) |

≤3‰ (cut) |

||||||

Bonding Wire is one of the core materials in semiconductor packaging, primarily used for electrical connections between the chip and the external circuit.

Shares similar production processes with photovoltaic ribbon products.

| Diameter | Weight | Elongation | Breaking Load | |

| µm | mil | mg/m | % | cN |

| 18±1 | 0.7 | 2.48-3.10 | ≥2 | >3 |

| 20±1 | 0.8 | 3.10-3.79 | ≥3 | >4 |

| 23±1 | 0.9 | 4.16-4.95 | ≥3 | >6 |

| 25±1 | 1 | 4.95-5.81 | ≥4 | >8 |

| 28±1 | 1.1 | 6.26-7.23 | ≥4.5 | >9 |

| 30±1 | 1.2 | 7.23-8.26 | ≥5 | >11 |

Previous

Next

Previous

Next

Recommended Products

undefined

Language

Language